Cutting Tools

Main content

AquaREVO Mills

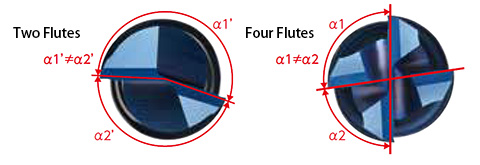

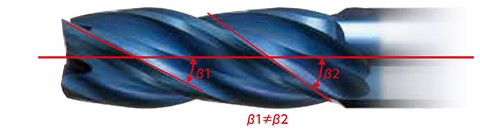

Adoption of unequally spaced blades and variable leads

Suppress chatter vibration and realize stable and highly efficient machining

Unequally spaced blades

Variable leads

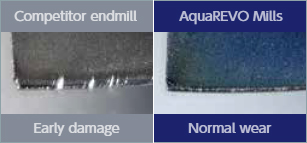

Comparison of cutting face

| Size | : | Ø6.0 Four flutes 2.5D G type (Gashland) |

Feed Speer | : | 1,270mm/min (0.04mm/t) |

| Cutting method | : | Side milling | Depth of Cut | : | ap9.0mm ae0.6mm |

| Work Material | : | SUS304 | Cutting Fluid | : | Water-soluble |

| Cutting Speed | : | 150mm/min (7,950min-1) |

Machine | : | Vertical M/C (HSK32E) |

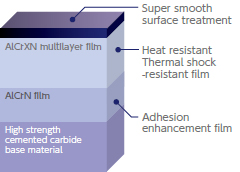

REVO-M coat with high heat resistance and thermal shock resistance demonstrates excellent durability in dry and wet processing

|

|

Suppresses the progress of corner wear,

maintains the cutting edge, and provides a long tool life

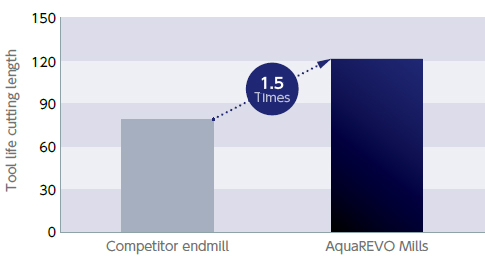

Comparison tool life

Comparison of wear (Cutting length 80m)

| Size | : | Ø6.0 Four flutes 2.5D type (Gashland) |

Feed Speed | : | 1,500mm/min (0.06mm/t) |

| Cutting method | : | Side milling | Depth of cut | : | ap12.0mm ae1.2mm |

| Work Material | : | S50C (180HB) | Cutting Fluid | : | Qater-soluble |

| Cutting Speed | : | 120mm/min (6,370min-1) | Machine | : | Vertical M/C (HSK63A) |