Cutting Tools

Main content

GSX MILL VL Roughing

Features a design optimized for unequal spacing of teeth and variable leads to improve chipping resistance and enable high-efficiency machining

Nick shape

|

|

Applicable work materials

|

Low-carbon steels SS400, S10C |

Carbon steels S45C, SCM440 |

Pre-hardened steels SUJ, NAK |

Tempered steels SKD, SKH |

Hardened steels Hardened Steels |

|

|---|---|---|---|---|---|

| 30 |

40 |

50 |

|||

|

Stainless steels SUS304 |

Heat-resistant alloy Ti/Ni Alloys |

Cast iron FC/FCD |

Aluminum alloy AC/ADC |

Copper/copper alloy Cu |

Graphite Graphite |

![]() : optimal

: optimal ![]() : applicable ×: not applicable No mark: not recommended

: applicable ×: not applicable No mark: not recommended

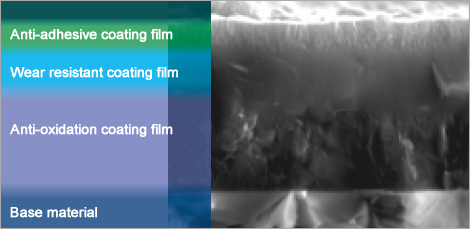

GSX II coating

- Achieves excellent heat resistance with enhanced oxidation resistance and heat dissipation

- Features a new layered structure for high hardness

- Optimizes the crystal structure of the film for increased resistance to wear and adhesion

Heat resistance far superior to competitors

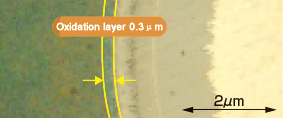

Oxidation resistance evaluation (calo test crater after being held for 1 hour in the atmosphere at 1,100°C)

| Coating (oxidation resistance temperature) | Calo test crater |

GSX II coating 1,100°C |

|

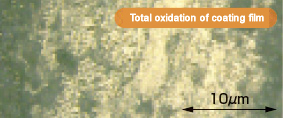

Company A C coating 1,200°C (Company A's listed value) |

|

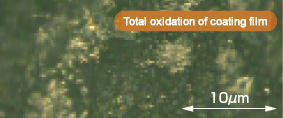

Company B D coating 1,300°C (Company B's listed value) |

|

Oxidation resistance tests conducted under NACHI standards showed GSX II coating limits oxidation to 0.3µm from the surface, whereas coating products of competitors resulted in

total oxidation of the coating layer.