Cutting Tools

Main text

Hyper Z Low Spiral Tap

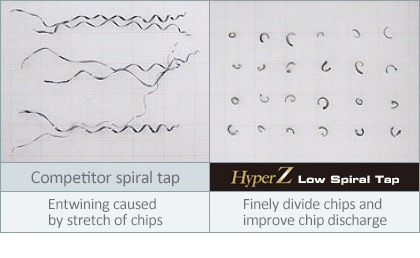

Outstanding chip evacuation regardless of processing machine

By adopting a low spiral flute shape and optimizing the helix angle, the strength of the cutting edge is improved, and chips are finely divided. Stable machining is achieved even in horizontal machining centers which chip clogging and entanglement problems are likely to occur.

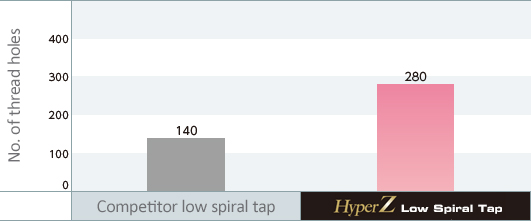

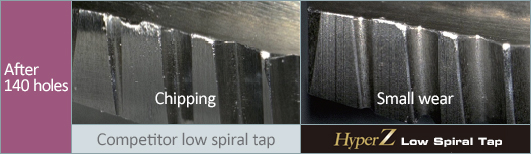

Long tool life even which machining high hardness steel

Our uniquely developed material with both hardness and toughness, and special surface treatment suppress blade chipping and wear even with hard high-hardness steel and ductile cast iron.

| Cutting conditions |

||

|---|---|---|

| Size : M6×1 | Cutting speed : 5m/min | Hotizontal machining center / Synchro tapper |

| Work Material : SCM440H (44HRC) | Depth (blind hole) : 7mm | Tap paste |