Cutting Tools

Main text

Dual Cut Hob

Excellent Material

| Excellent material for hob having Wear Resistance and Chipping Resistance | ||||||

|

||||||

| Optimum Coating in Dry Cutting Optimum Hob Design in Dry Cutting |

Typical structure of chip by wet cutting

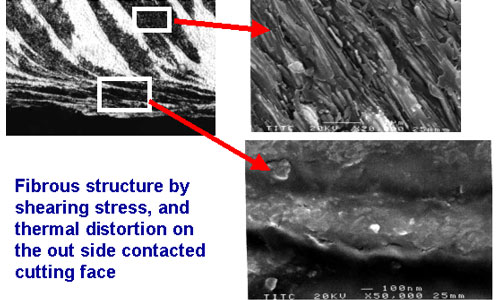

Typical structure of chip by dry hobbing

SEM image of adhesive metal on cutting face by dry hobbing

Heat Transmittal and Diffusion

| TiCN Coating |  |

| TiAlN Coating |  |

Comparison between dry and conventional

| HSS Hob | Carbide Hob | ||

| Coolant | Non water soluble oil | Dry | Dry |

| Speed | 80 - 120 | 120 - 160 | 300 - 350 |

| Efficiency | 1 | 1.5 | 3 |

| Tool Life | 1 | (2 - 5) | (4 - 10) |

| Cost | 1 | (1.5 - 2) | (3 - 4) |

| Accuracy | |||

| Reliability | |||

| Workability | |||

| Workshop environment | |||

Recommended cutting conditions

Summary of dry hobbing