商品情報

Products

Robots

Handling

■Wall-Mounted Robot for Use in Compact Spaces MZ12W

●Compact Design

- Operates over a wide area, eliminating the need for a drive unit.

- Pendulum-like motion of the first axis allows operation in narrow layouts, such as hallways.

●High Speed and High Precision

- Vertical orientation of the first axis and fine-motion functionality improve trajectory accuracy.

●Powerful Wrist

- Wrist torque at least twice that of the MZ12H.

- Suitable for large workpieces and tooling.

Application examples

Optimized for rack storage in board transport applications

→Reduced risk of dust adhering to boards, as the tooling is positioned above the robot arm.

Multiple units can be used for rack-to-rack loading without a traveling device.

Compact Design

・Normal robot case

→Maintenance is not easy because the robot is placed in front of the opening.

Requires installation of traveling axles, expensive due to one-of-a-kind design, width of traveling axles required

・In the case of MZ12W

→Can be installed without obstructing fixture openings, enhancing machine maintenance access.

Wide operating range allows equipment to be reached without traveling axles, and low cost

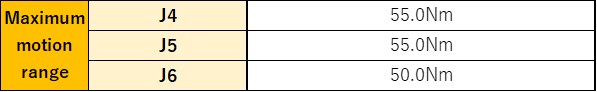

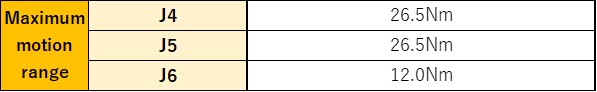

Powerful Wrist

More than twice the wrist torque of MZ12H for large workpieces and hands

In case of MZ12W

In case of MZ12H

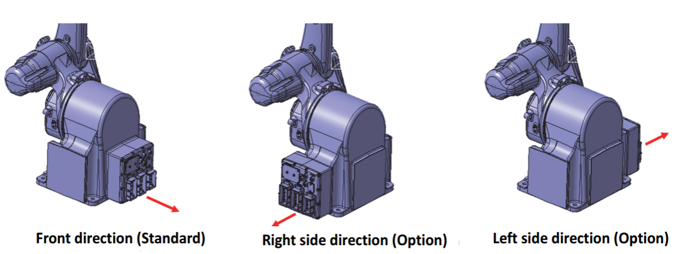

Harness selectable in each direction

Selectable harnesses in each direction provide flexibility in various layouts

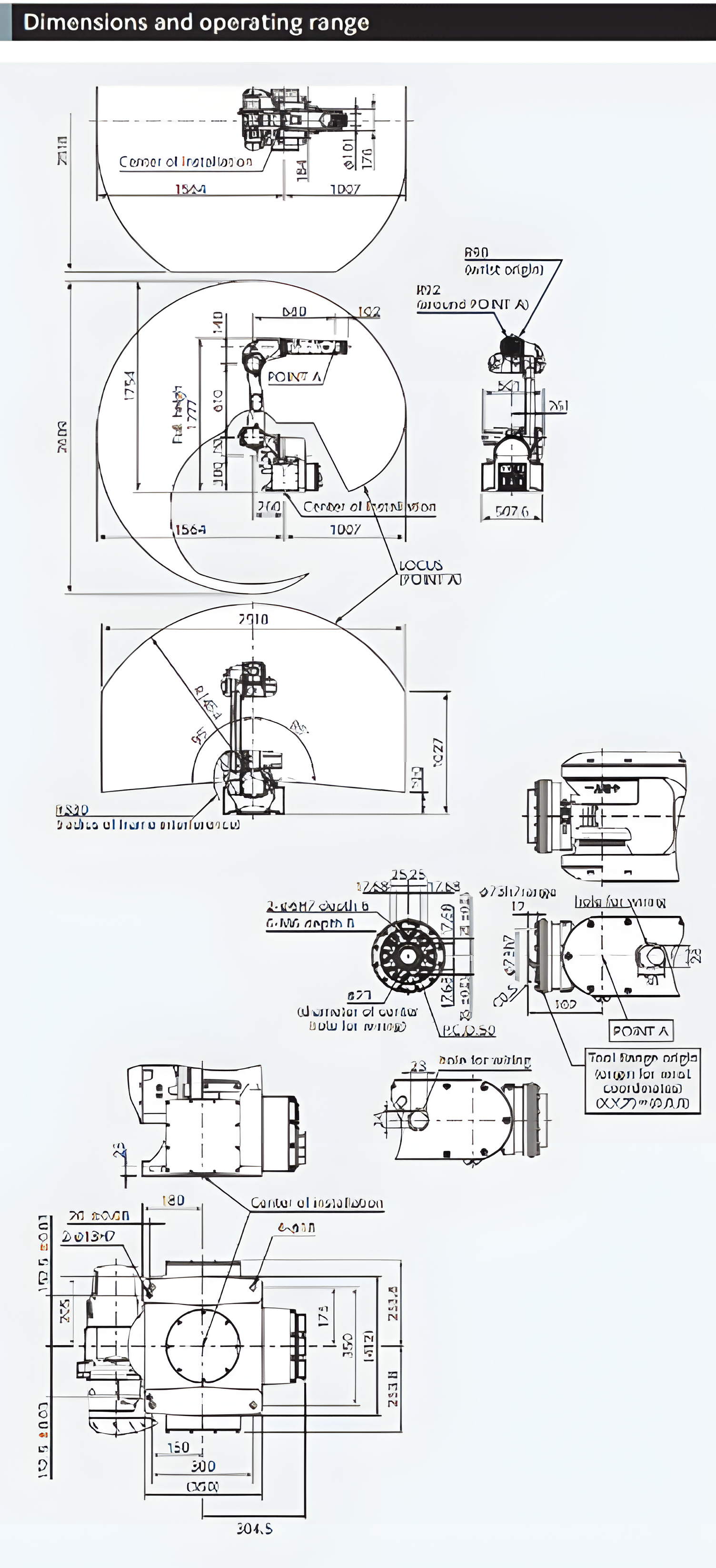

Robot dimensions and operating range

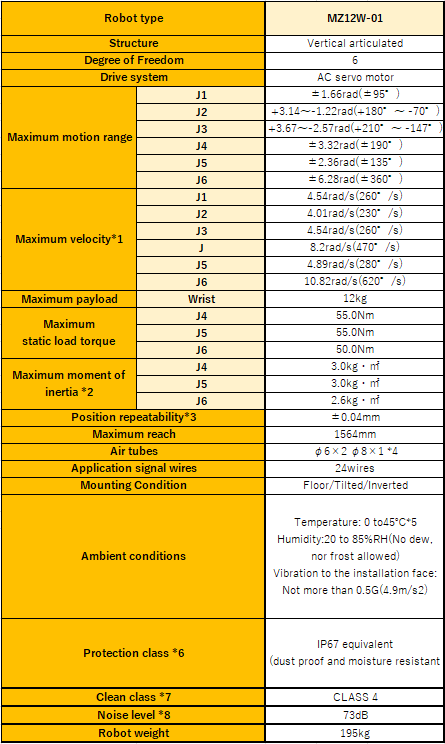

MZ12W specifications

1[rad] = 180/π[°], 1[N・m] = 1/9.8[kgf・m]

※ Axes 1 to 6 are displayed as J1 to J6 on the controller screen.

※ Due to product improvement, ratings, specifications, dimensions, etc. are subject to change without notice.

※ Not explosion-proof

*1: The maximum velocity in the chart is the maximum value. It will change depending on the operation program and the wrist load condition.

*2: Maximum moment of inertia of a wrist changes depending on the load condtion

*3: JIS B 8432 conformance

*4: When selecting the built-in solenoid valve of clean specification, air tube is φ6x1.

*5:Using at 1,000m or lower sea level.Ambint temperature has limitations when allowable altitude is exceeded

*6:Liquid such as organic compound, acidity, alkalinity, chlorine or gasoline cutting fluid which deteriorates the seal material is not available to use.

The wire-harness portion is IP65 equivalent, and the robot controller CFDs-3000 is IP20 equivalent. See the figure of "Protection class"below.

*7:Based on internal assessment in accordance with ISO14644-1. To ensure cleanliness, install the robot in clean room with downflow. The robot is not packed in a dustproof package, so dust removal and wiping and cleaning of the robot are required when bringing it into the clean room.

*8:Robot noise is A-weighted equivalent sound level measured under" JIS Z 8737-1" (ISO 11201) with maximum payload and maximum velocity.

カタログダウンロード

Catalog Download

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.