商品情報

Products

Cutting Tools

Carbide Drills

■Crystal Diamond Coated Drills

Suitable for cutting holes in CFRP

CFRP is a composite formed by curing carbon fiber impregnated with resin.

It is highly resistant to wear, heat, and oxidation, and also boasts excellent thermal elasticity. It has strength and stiffness comparable to iron, steel, and other metals, yet is far lighter, a characteristic that makes it a popular choice of material for building aircraft.

CFRP, however, has the following drawbacks:

- High hardness of carbon fiber

- Easily delaminates due to low resin strength

- Low cutting-heat resistance of resin at 200?

Crystal diamond coated drills feature a unique cutting edge design that delivers excellent cutting performance and diamond coating with enhanced crystallinity. The reduced cutting resistance and increased resistance to wear will ensure a longer tool life for use with difficult-to-machine materials.

Features

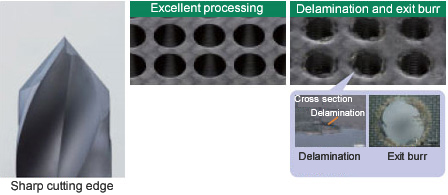

A cutting edge design that minimizes cutting resistance

Sharp cutting edge that ensures a clean cut through carbon fiber

Cutting resistance is minimized to help prevent CFRP delamination and exit burring

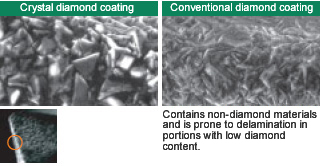

Crystal diamond coating with increased crystallinity

Newly developed crystal diamond coating offers improved wear resistance and a longer tool life, made possible by increasing the crystallinity

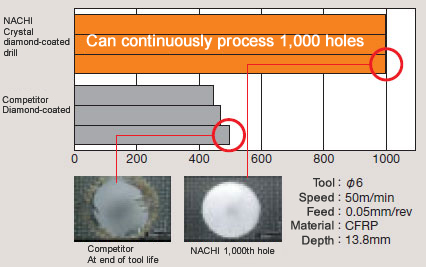

CFRP machining comparison

Tool life comparison

Number of holes until delamination (0.5 mm) occurs

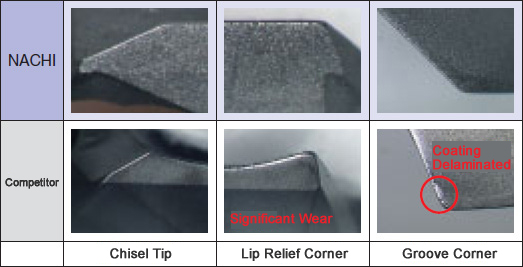

Wear comparison

Wear after 1,120 holes (NACHI) 350 holes (Competitor)

CFRP hole drilling

カタログダウンロード

Catalog Download

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.