商品情報

Products

Cutting Tools

Thread forming taps

■ZT Forming Tap

Overwhelmingly long tool life and low torque forming tap “ZT Forming Tap”

As for the material, we have developed a new cobalt high speed steel exclusively for forming taps. By refining the material structure, hardness is improved while maintaining the toughness.

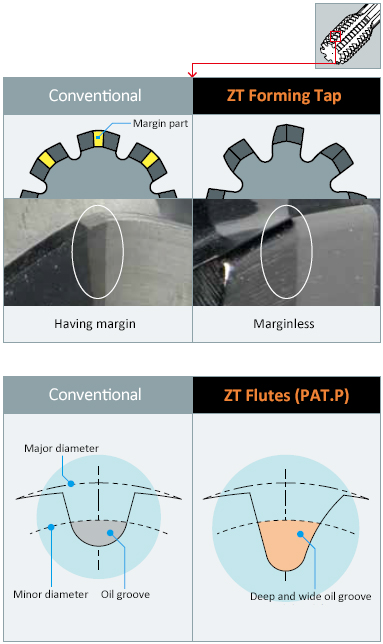

As for the geometry, a design that eliminates the margin on the thread forming chamfer has been adopted. This decreases the contact area between the tool and work material which significantly reduces wear and frictional resistance due to rubbing. The newly developed “ZT flute” is used for the oil groove shape. A deep and wide oil groove design allows for high lubrication performance.

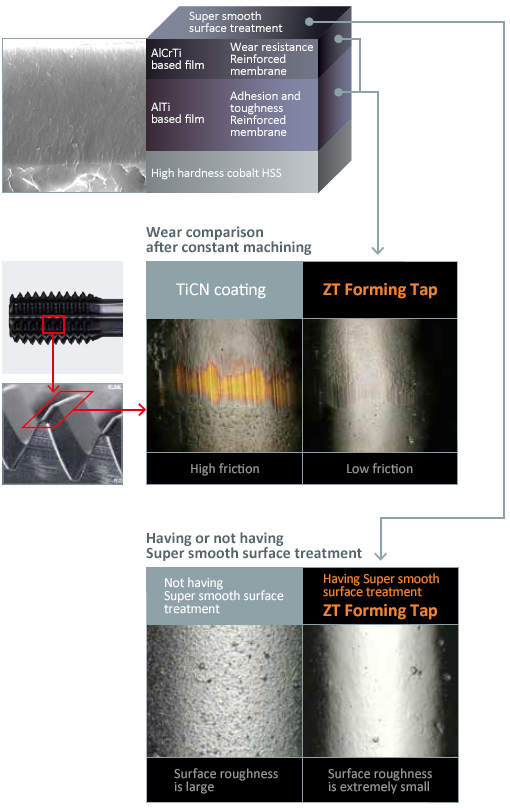

ZT coating combines an Aluminum Titanium film with improved toughness and an ultra-smoothing polishing treatment to achieve both excellent wear resistance, heat resistance, and low friction. ZT Forming Tap is compatible with a wide range of work materials.

Coating

ZT coating maximizes film performance by combining AlTi-based film that improved toughness. and Super smooth surface treatment. Super smooth surface treatment reduces surface roughness and suppresses coating load and frictional resistance.

Geometry

Margin-less is adopted for forming parts of the thread. By reducing the contact area, frictional resistance is suppressed and Reduction of machining torque and suppression of wear progress.

The newly developed oil groove shape ZT Flutes (PAT.P) widens the oil groove deeply and greatly to improve the flow rate of cutting fluid. Demonstrates high lubrication performance even in horizontal machining center where cutting fluid is difficult to reach.

Products Information

カタログダウンロード

Catalog Download

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.