商品情報

Products

Cutting Tools

Carbide End Mills

■AquaREVO Mills

The new carbide endmill

AquaREVO Mills were born in AquaREVO Series

that material, design, coating are completely all renewed

The new carbide base material for endmill with

both hardness and toughness

Adoption of unequally spaced blades and variable leads

Suppress chatter vibration and realize stable and highly efficient machining

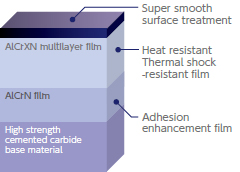

REVO-M coat with high heat resistance

and thermal shock resistance demonstrates

excellent durability in dry and wet processing

Compatible with a wide range of materials

from Structural steel to Stainless steel and Hardened steel

Adoption of unequally spaced blades and variable leads

Suppress chatter vibration and realize stable and highly efficient machining

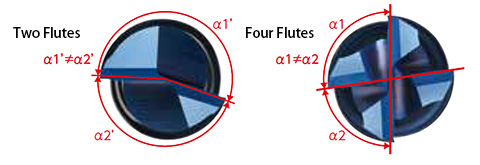

●Unequally spaced blades

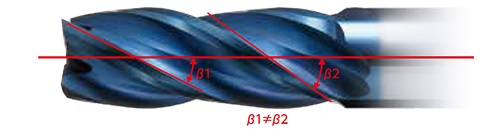

●Variable leads

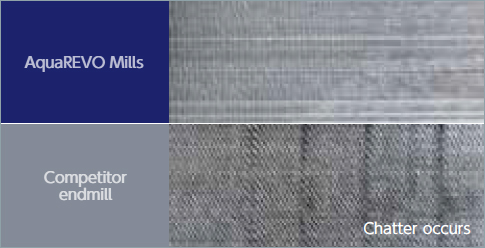

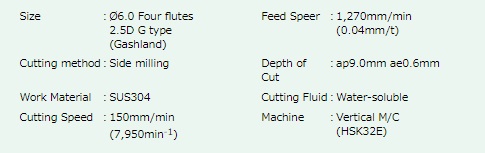

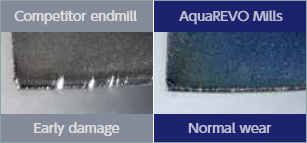

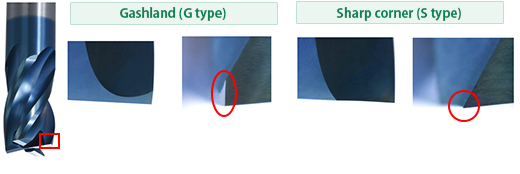

●Comparison of cutting face

REVO-M coat with high heat resistance and thermal shock resistance demonstrates excellent durability in dry and wet processing

- High heat resistance (1100°C) and excellent thermal shock resistance are realized by adopting a new AlCrXN film

- Ensire wear resistance (3300HV) by optimizing film formation conditions

- Improved chipping resistance due to increased adhesion resistance by super smooth surface treatment Suppresses damage caused by chip biting

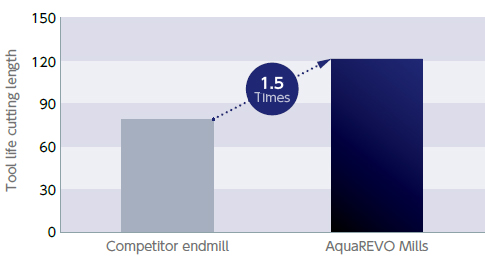

Suppresses the progress of corner wear,

maintains the cutting edge, and provides a long tool life

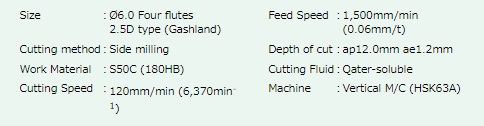

●Comparison tool life

●Comparison of wear (Cutting length 80m)

Type

There are two types of cutting edge shape for carbide end mills: gashland and sharp corner.

About the difference of the cutting edge and the use

The cutting edge corner of the end mill is driven in from four sides of the helix angle, the rake angle, the radial relief angle, and axial relief angle, resulting in a smaller blade angle.

Chipping of the corners is likely to occur for machining with large vibrations and impacts, such as high depth of cut, high feed, and grooving.

As a countermeasure, when grooving the bottom blade (gash), the strength of the cutting edge may be increased by putting the rake face of the bottom blade to the outer peripheral corners. That's "Gashland (G type)".

However, when the gashland is attached, the cutting edge corner moves backward from the outer diameter direction, in a strict sense, corner remains on the machined surface.

Use a Sharp corner (S type) end mill to remove the rest of the corner (pin angle).

カタログダウンロード

Catalog Download

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.