商品情報

Products

Cutting Tools

Carbide End Mills

■GS MILL Hard

●Super high speed milling

- Newly developed ultra aluminum rich Al-Ti-Cr multi-layered "GS Hard Coat" allows super high speed milling up to 800m/min.

●High rigidity

- Unique geometry improves chip removal and tool rigidity.

●Long tool life

- Ultra micro grain low-cobalt carbide with high hardness improves tool material strength and curtails micro-plastic deformation that can occur at very high speeds. The result is better durability.

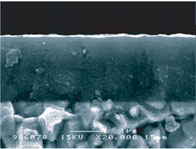

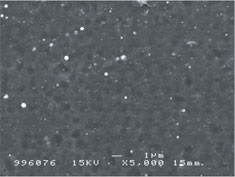

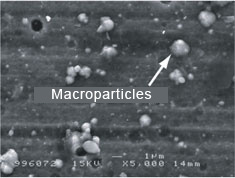

GS Hard Coat

Top layered film consists of newly developed ultra aluminum rich Al-Ti-Cr coating, with 3 times better oxidation resistance at 1,100 deg Centigrade.

Fewer macroparticles on film surface result in improved smoothness

GS Hard Coating

Conventional coating

New geometry

- Smoothly curved flute geometry improves chip removal

- Wide land improves tool regidity

Ext. Diameter 10 (6 Flutes) : SKD61 (53HRC)

Milling condition

Tool : GSH6100SF

Speed: 800m/min

(25,000min-1)

Feed : 10,500mm/min

(0.07mm/tooth)

Material : SKD61 (53HRC)

Coolant : Air blow

Cutting length : 75m

Ext. Diameter 10 : SKD11 (60HRC)

Milling condition

Tool : GSH6100SF

Speed: 70m/min

(2,230min-1)

Feed : 900mm/min

(0.067mm/tooth)

Material : SKD11 (60HRC)

Coolant : Air blow

Cutting length : 70m

Milling with GS MILL hard

Milling condition

Tool : GSH6100SF

Speed : 800m/min

(25, 000min-1)

Feed : 10, 500mm/min (0.07mm/tooth)

Material : SKD61 (53HRC)

Coolant : Air blow

Cutting length:75m

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.