商品情報

Products

Cutting Tools

Carbide End Mills

■Diamond Coated End Mills

●Diamond coating

- 100% pure diamond coating.

- Suitable for nonferrous metals,nonmetals.

●Long tool life

- The tool life is 10 times of conventional carbide End mill in milling high silicon aluminum.

●Precision

- It is possible to acquire excellent surface roughness.

- Diamond Coated End Mill Two Flutes

- Diamond Coated Stub End Mill

- Diamond Coated Ball End Mill

●Series

●100% pure diamond coating

Applicable on unique cutting edge

Applicable on Micro tool

Cross section photo of diamond film

Work materials of Diamond Coated tools

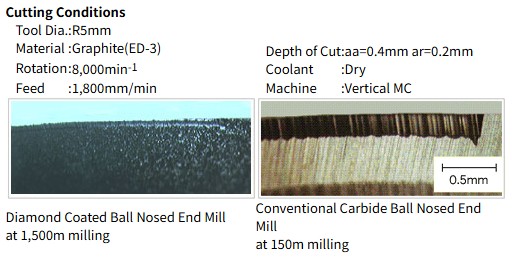

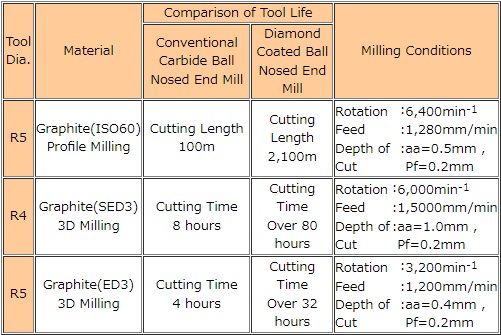

Diamond Coated Ball Nosed End Mills

Over 10times longer life than Conventional Carbide Ball Nosed End Mills.

Excellent Performance for Cast Iron FC250

Tool Dia. : R2mm 2Flutes

Material : FC250

Depth of Cut : aa=0.5mm, Pf=0.4mm

Rotation : 24,000min

Coolant : Air blow

Feed : 2,000mm/min

Machin : Vertical MC

Over 10times Longer Tool Life than Conventional Carbide End Mills.

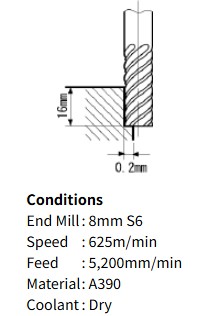

Excellent Performance for A390

Tool Dia.: 8mm 4Flutes

Feed: 1,000mm/min

Material : A390

Depth of Cut : aa=18mm ar=0.2mm

(Al-17%SiAlloy)

Coolant : Dry

Milling Speed : 200m/min

Machine : Vertical MC

Over 10times Longer Tool Life than Conventional Carbide End Mills.

Dry milling by Diamond Coated End Mill

Milling Aluminum alloy by Diamond Coated End Mill

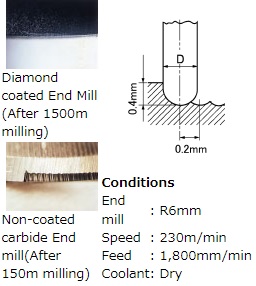

Conditions

End mill : 2mm

Speed : 150m/min

Feed: 1,000mm/min

Material : ADC12

Coolant : Emulsion

Diamond Coated Ball Nosed End Mills

Innovation Technology of Mold & Die manufacturing Ideal

Cutting Tool for Graphite Electrodes

Realization of Unmanned Operation around the Clock!

High speed Milling by Diamond Coated End Mill

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.