商品情報

products

Products

KiwgKjo6YmVmb3JlLCAqOjphZnRlciB7LXdlYmtpdC1ib3gtc2l6aW5nOiBib3JkZXItYm94O2JveC1zaXppbmc6IGJvcmRlci1ib3g7fQ0KLmlubmVye21heC13aWR0aDogMTEyMHB4O21hcmdpbjogYXV0bzt3aWR0aDogOTQlO30NCnRhYmxle3dpZHRoOiAxMDAlO3RhYmxlLWxheW91dDogZml4ZWQ7Ym9yZGVyLWNvbGxhcHNlOiBjb2xsYXBzZX0NCnRoLHRke3BhZGRpbmc6IDFyZW07Ym9yZGVyOiAxcHggc29saWQgI2NjYzt9DQp0ZHt2ZXJ0aWNhbC1hbGlnbjogdG9wO30NCnVsLG9se3BhZGRpbmctbGVmdDogMjBweDt9DQpsaStsaXttYXJnaW4tdG9wOiAuNXJlbTt9DQpkdHtmb250LXdlaWdodDogYm9sZDt9DQpkZHttYXJnaW4tbGVmdDogMDttYXJnaW4tdG9wOiAuNXJlbTt9DQpkZCtkdHttYXJnaW4tdG9wOiAxcmVtO30NCmltZ3ttYXgtd2lkdGg6IDEwMCU7aGVpZ2h0OiBhdXRvfQ0KYSB7dGV4dC1kZWNvcmF0aW9uOiBub25lO2JhY2tncm91bmQtY29sb3I6IHRyYW5zcGFyZW50O30NCmE6aG92ZXIge3RleHQtZGVjb3JhdGlvbjogdW5kZXJsaW5lO30NCmlucHV0LHNlbGVjdCx0ZXh0YXJlYXtib3JkZXI6IDFweCBzb2xpZCAjY2NjO3BhZGRpbmc6IC4yNXJlbSAuNXJlbTt9DQppbnB1dCwgYnV0dG9uLCBzZWxlY3QsIG9wdGdyb3VwLCB0ZXh0YXJlYSB7bWFyZ2luOiAwO2ZvbnQtZmFtaWx5OiBpbmhlcml0O2ZvbnQtc2l6ZTogaW5oZXJpdDtsaW5lLWhlaWdodDogaW5oZXJpdDtvdXRsaW5lOiBub25lO30NCmxhYmVsIHtjdXJzb3I6IHBvaW50ZXI7ZGlzcGxheTogYmxvY2s7bWFyZ2luLWJvdHRvbTogLjI1cmVtO21hcmdpbi1yaWdodDogMXJlbTt9DQppbnB1dFt0eXBlPSd0ZXh0J117YXBwZWFyYW5jZTogbm9uZTstd2Via2l0LWFwcGVhcmFuY2U6IG5vbmU7LW1vei1hcHBlYXJhbmNlOiBub25lO3dpZHRoOiAxMDAlO30NCmlucHV0W3R5cGU9J2NoZWNrYm94J10saW5wdXRbdHlwZT0ncmFkaW8nXXttYXJnaW4tcmlnaHQ6IC41cmVtO30NCmlucHV0W3R5cGU9J3N1Ym1pdCdde2JvcmRlcjogbm9uZTtkaXNwbGF5OiBibG9jazttYXJnaW46IGF1dG87cGFkZGluZzogLjc1cmVtIDVyZW07Y3Vyc29yOiBwb2ludGVyO30NCi5ibWhfYnRuIGF7Ym9yZGVyLXJhZGl1czogMTAwdmg7YmFja2dyb3VuZC1jb2xvcjogIzk5OTtwYWRkaW5nOiAuNzVyZW07Y29sb3I6ICNmZmY7dGV4dC1kZWNvcmF0aW9uOiBub25lO2Rpc3BsYXk6IGlubGluZS1ibG9jazt9DQouYm1oX2J0biBhIHNwYW57cG9zaXRpb246IHJlbGF0aXZlO3BhZGRpbmctcmlnaHQ6IDJyZW07cGFkZGluZy1sZWZ0OiAxLjVyZW07ZGlzcGxheTogaW5saW5lLWJsb2NrO30NCi5ibWhfYnRuIGEgc3Bhbjo6YWZ0ZXJ7Y29udGVudDogIiI7bWFyZ2luOiBhdXRvO3JpZ2h0OiAuNXJlbTtwb3NpdGlvbjogYWJzb2x1dGU7dG9wOiAwO2JvdHRvbTogMDt3aWR0aDogNnB4O2hlaWdodDogNnB4O2JvcmRlci10b3A6IDJweCBzb2xpZCAjZmZmO2JvcmRlci1yaWdodDogMnB4IHNvbGlkICNmZmY7dHJhbnNmb3JtOiByb3RhdGUoNDVkZWcpO30NCi5ibWhfYnRuIGE6aG92ZXJ7YmFja2dyb3VuZC1jb2xvcjogIzc3Nzt0ZXh0LWRlY29yYXRpb246bm9uZTt9DQouYm1oX2xpbmsgYXtwYWRkaW5nLWxlZnQ6IDFyZW07cG9zaXRpb246IHJlbGF0aXZlO2NvbG9yOiAjMzMzO2Rpc3BsYXk6IGlubGluZS1ibG9jazt9DQouYm1oX2xpbmsgYTo6YmVmb3Jle2NvbnRlbnQ6ICIiO21hcmdpbjogYXV0bztsZWZ0OiAwO3Bvc2l0aW9uOiBhYnNvbHV0ZTt0b3A6Y2FsYyguNXJlbSArIDFweCk7d2lkdGg6IDRweDtoZWlnaHQ6IDRweDtib3JkZXItdG9wOiAycHggc29saWQgIzMzMztib3JkZXItcmlnaHQ6IDJweCBzb2xpZCAjMzMzO3RyYW5zZm9ybTogcm90YXRlKDQ1ZGVnKTt9DQpkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXYsZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2LGRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdixmb3JtW2lkXj0iZm9ybWdyaWQxY29sIl0sZm9ybVtpZF49ImZvcm1ncmlkM2NvbCJdLGZvcm1baWRePSJmb3JtZ3JpZDRjb2wiXXtkaXNwbGF5OiBmbGV4O2ZsZXgtd3JhcDogd3JhcDt9DQpkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXY+ZGl2LGRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXYsZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdiwNCmRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2LGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2LGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2e3dpZHRoOiAxMDAlO30NCmRpdltpZF49Imxpc3RncmlkMmNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMiksZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobisyKSxkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLA0KZGl2W2lkXj0iZm9ybWdyaWQyY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMiksZGl2W2lkXj0iZm9ybWdyaWQzY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMiksZGl2W2lkXj0iZm9ybWdyaWQ0Y29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMil7bWFyZ2luLXRvcDogMzBweDt9DQouYm1oX2NhbGVuZGFyIGltZywuYm1oX2NhbGVuZGFyIGltZ3ttYXgtd2lkdGg6IDkwcHg7bWFyZ2luLWxlZnQ6IC41cmVtO30NCi5ibWhfY2FsZW5kYXIgc3BhbiwuYm1oX2NhbGVuZGFyPnNwYW4sLmJtaF9jYWxlbmRhcj5zcGFue2Rpc3BsYXk6IGZsZXg7YWxpZ24taXRlbXM6IGZsZXgtZW5kO2ZsZXgtd3JhcDogd3JhcDt9DQouYm1oX2NhbGVuZGFyPnNwYW4+aW5wdXQsLmJtaF9jYWxlbmRhcj5zcGFuPmlucHV0LC5ibWhfY2FsZW5kYXI+c3Bhbj5pbnB1dHt3aWR0aDogOXJlbTt9DQouYm1oX2NhbGVuZGFyPnNwYW4+aW1nOmxhc3QtY2hpbGR7bWFyZ2luLXRvcDogLjVyZW07fQ0KQG1lZGlhIChtaW4td2lkdGg6IDU3NnB4KSB7DQoJbGFiZWwge2Rpc3BsYXk6IGlubGluZS1ibG9jazt9DQp9DQpAbWVkaWEgKG1pbi13aWR0aDogNzY4cHgpIHsNCglkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDUwJSAtIDE1cHgpO21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoMm4pLGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgybil7bWFyZ2luLXJpZ2h0OiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpe21hcmdpbi10b3A6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMyksZGl2W2lkXj0iZm9ybWdyaWQ0Y29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMyl7bWFyZ2luLXRvcDogMzBweDt9DQoNCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDUwJSAtIDE1cHgpO21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoMm4pLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgybil7bWFyZ2luLXJpZ2h0OiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpe21hcmdpbi10b3A6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMyksZGl2W2lkXj0iZm9ybWdyaWQzY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMyl7bWFyZ2luLXRvcDogMzBweDt9DQoNCglkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDUwJSAtIDE1cHgpO21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQyY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoMm4pLGRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgybil7bWFyZ2luLXJpZ2h0OiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpe21hcmdpbi10b3A6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkMmNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMyksZGl2W2lkXj0iZm9ybWdyaWQyY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMyl7bWFyZ2luLXRvcDogMzBweDt9DQp9DQpAbWVkaWEgKG1pbi13aWR0aDogOTkycHgpIHsNCglkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDI1JSAtIDE4cHgpO21hcmdpbi1yaWdodDogMjRweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobisyKSxkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQobisyKXttYXJnaW4tcmlnaHQ6IDI0cHg7fQ0KCWRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKDRuKSxkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQoNG4pe21hcmdpbi1yaWdodDogMDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobiszKSxkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQobiszKXttYXJnaW4tdG9wOiAwO30NCg0KCWRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXYsZGl2W2lkXj0iZm9ybWdyaWQzY29sIl0+Zm9ybT5kaXZ7d2lkdGg6IGNhbGMoMzMuMzMzJSAtIDIwcHgpO21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoMm4pLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgybil7bWFyZ2luLXJpZ2h0OiAzMHB4O30NCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZCgzbiksZGl2W2lkXj0iZm9ybWdyaWQzY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKDNuKXttYXJnaW4tcmlnaHQ6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKDMpLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgzKXttYXJnaW4tdG9wOiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzQpLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzQpe21hcmdpbi10b3A6IDMwcHg7fQ0KfQ==

Cutting Tools

Carbide Drills

■AQUA Drill EX FLAT

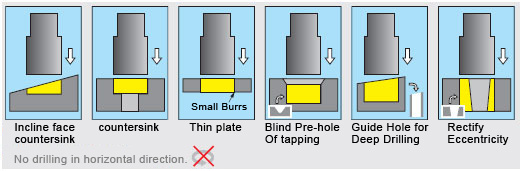

●Drill for counter boring has great performance.

- Spot facing machining capability for a wide range of applications such as spot facing on slope, correction of eccentric holes, and thin plate machining.

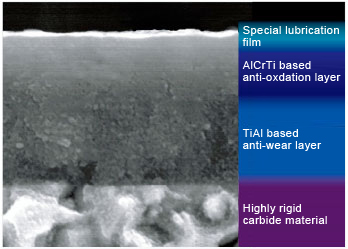

●Aqua EX Coating

- Better heat and wear resistance from Aqua EX coating for a super long life.

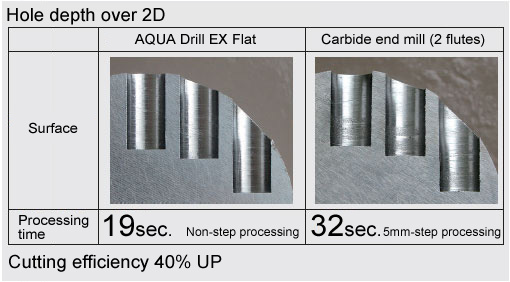

●Drilling efficiency improvement due to reduced processing time

- Counter boring and guide hole drilled at the same time.

- Effective screw length is assured when drilling set screw holes in thin material, without increasing work.

Performance opens up extensive applications

Only under 1.9mm are applicable for stainless steels (SUS304)

Cutting resistance on 45° angled surface

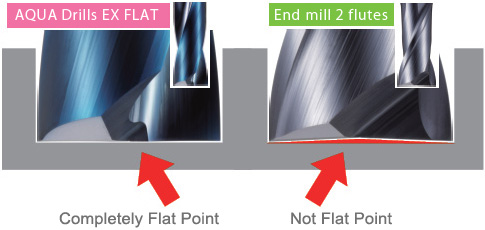

Absolutely flat drill face

AQUA EX Coating

Improved resistance to oxidation, heat and wear

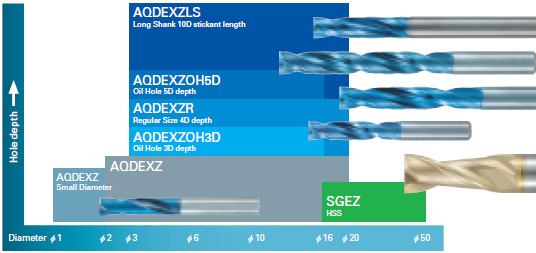

AQUA Drill EX Flat lineup

Multi-functional flat drill

High-efficiency One shot drilling with no point holes

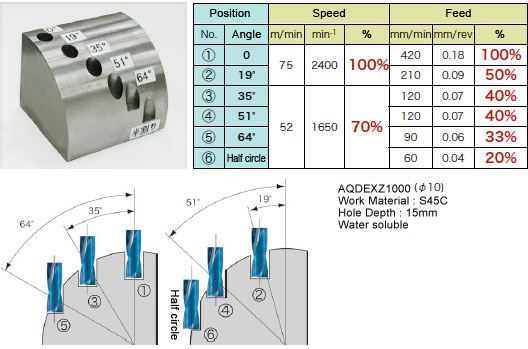

Cutting condition on inclined hole drilling

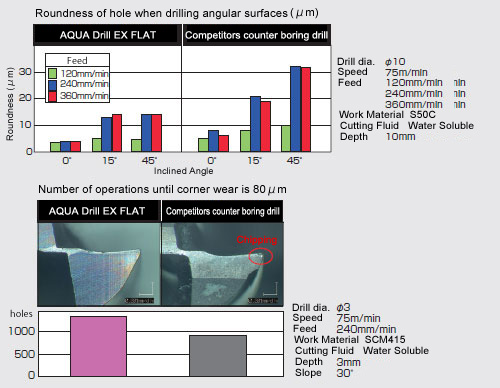

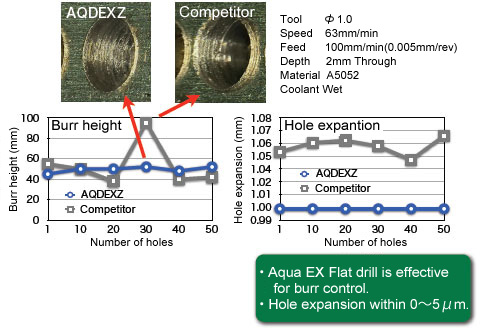

Comparison with competitors counter boring drill

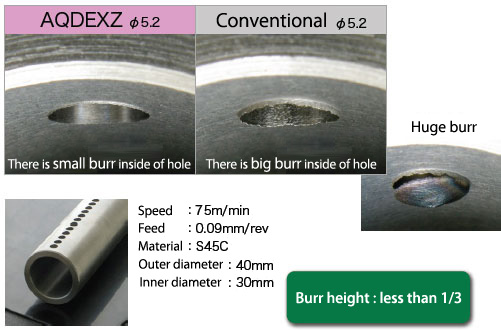

Burr size comparisor at exit of hole inside pipe materials

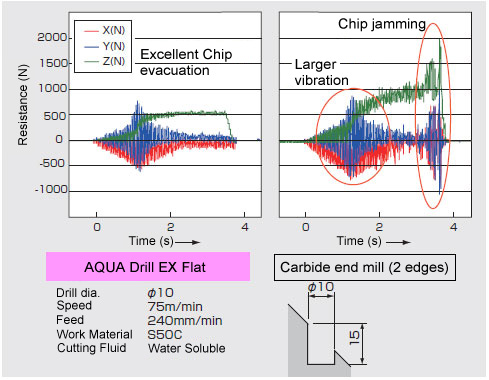

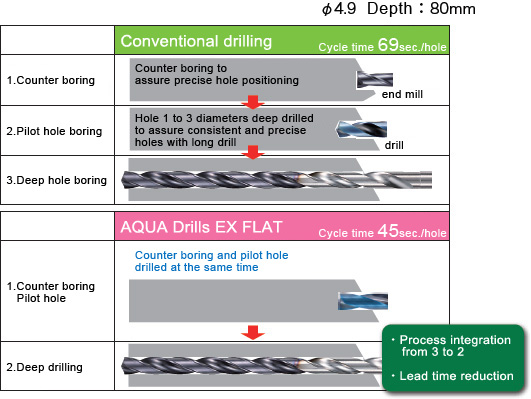

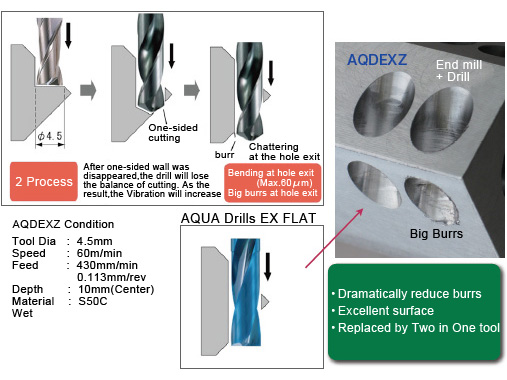

Drilling process comparison in guide holes

Fuel pump parts drilling on the sloped surface

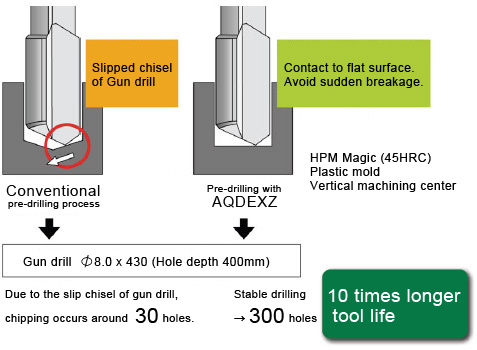

Gun Drill tool life extension with AQDEXZ as pre-drilling tool

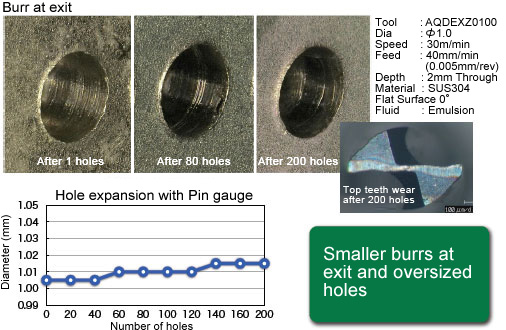

Example for stainless steels (SUS304)

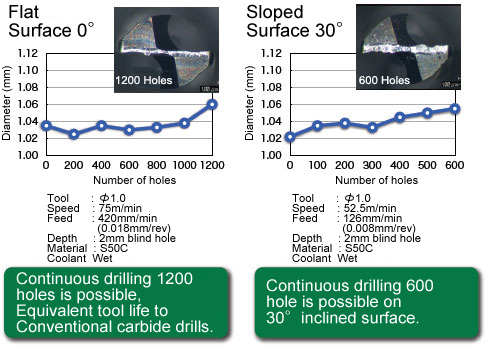

Expansion of the hole diameter for S50C

Hole accurocy of drilling thin plates of aluminum alloy (A5052)

Introduction

Countersink

Comparison of burrs at the hole exit(1)

Comparison of burrs at the hole exit(2)

Drilling on the sloped surface.

カタログダウンロード

Catalog Download

関連リンク

Related Links

KiwgKjo6YmVmb3JlLCAqOjphZnRlciB7LXdlYmtpdC1ib3gtc2l6aW5nOiBib3JkZXItYm94O2JveC1zaXppbmc6IGJvcmRlci1ib3g7fQ0KLmlubmVye21heC13aWR0aDogMTEyMHB4O21hcmdpbjogYXV0bzt3aWR0aDogOTQlO30NCnRhYmxle3dpZHRoOiAxMDAlO3RhYmxlLWxheW91dDogZml4ZWQ7Ym9yZGVyLWNvbGxhcHNlOiBjb2xsYXBzZX0NCnRoLHRke3BhZGRpbmc6IDFyZW07Ym9yZGVyOiAxcHggc29saWQgI2NjYzt9DQp0ZHt2ZXJ0aWNhbC1hbGlnbjogdG9wO30NCnVsLG9se3BhZGRpbmctbGVmdDogMjBweDt9DQpsaStsaXttYXJnaW4tdG9wOiAuNXJlbTt9DQpkdHtmb250LXdlaWdodDogYm9sZDt9DQpkZHttYXJnaW4tbGVmdDogMDttYXJnaW4tdG9wOiAuNXJlbTt9DQpkZCtkdHttYXJnaW4tdG9wOiAxcmVtO30NCmltZ3ttYXgtd2lkdGg6IDEwMCU7aGVpZ2h0OiBhdXRvfQ0KYSB7dGV4dC1kZWNvcmF0aW9uOiBub25lO2JhY2tncm91bmQtY29sb3I6IHRyYW5zcGFyZW50O30NCmE6aG92ZXIge3RleHQtZGVjb3JhdGlvbjogdW5kZXJsaW5lO30NCmlucHV0LHNlbGVjdCx0ZXh0YXJlYXtib3JkZXI6IDFweCBzb2xpZCAjY2NjO3BhZGRpbmc6IC4yNXJlbSAuNXJlbTt9DQppbnB1dCwgYnV0dG9uLCBzZWxlY3QsIG9wdGdyb3VwLCB0ZXh0YXJlYSB7bWFyZ2luOiAwO2ZvbnQtZmFtaWx5OiBpbmhlcml0O2ZvbnQtc2l6ZTogaW5oZXJpdDtsaW5lLWhlaWdodDogaW5oZXJpdDtvdXRsaW5lOiBub25lO30NCmxhYmVsIHtjdXJzb3I6IHBvaW50ZXI7ZGlzcGxheTogYmxvY2s7bWFyZ2luLWJvdHRvbTogLjI1cmVtO21hcmdpbi1yaWdodDogMXJlbTt9DQppbnB1dFt0eXBlPSd0ZXh0J117YXBwZWFyYW5jZTogbm9uZTstd2Via2l0LWFwcGVhcmFuY2U6IG5vbmU7LW1vei1hcHBlYXJhbmNlOiBub25lO3dpZHRoOiAxMDAlO30NCmlucHV0W3R5cGU9J2NoZWNrYm94J10saW5wdXRbdHlwZT0ncmFkaW8nXXttYXJnaW4tcmlnaHQ6IC41cmVtO30NCmlucHV0W3R5cGU9J3N1Ym1pdCdde2JvcmRlcjogbm9uZTtkaXNwbGF5OiBibG9jazttYXJnaW46IGF1dG87cGFkZGluZzogLjc1cmVtIDVyZW07Y3Vyc29yOiBwb2ludGVyO30NCi5ibWhfYnRuIGF7Ym9yZGVyLXJhZGl1czogMTAwdmg7YmFja2dyb3VuZC1jb2xvcjogIzk5OTtwYWRkaW5nOiAuNzVyZW07Y29sb3I6ICNmZmY7dGV4dC1kZWNvcmF0aW9uOiBub25lO2Rpc3BsYXk6IGlubGluZS1ibG9jazt9DQouYm1oX2J0biBhIHNwYW57cG9zaXRpb246IHJlbGF0aXZlO3BhZGRpbmctcmlnaHQ6IDJyZW07cGFkZGluZy1sZWZ0OiAxLjVyZW07ZGlzcGxheTogaW5saW5lLWJsb2NrO30NCi5ibWhfYnRuIGEgc3Bhbjo6YWZ0ZXJ7Y29udGVudDogIiI7bWFyZ2luOiBhdXRvO3JpZ2h0OiAuNXJlbTtwb3NpdGlvbjogYWJzb2x1dGU7dG9wOiAwO2JvdHRvbTogMDt3aWR0aDogNnB4O2hlaWdodDogNnB4O2JvcmRlci10b3A6IDJweCBzb2xpZCAjZmZmO2JvcmRlci1yaWdodDogMnB4IHNvbGlkICNmZmY7dHJhbnNmb3JtOiByb3RhdGUoNDVkZWcpO30NCi5ibWhfYnRuIGE6aG92ZXJ7YmFja2dyb3VuZC1jb2xvcjogIzc3Nzt0ZXh0LWRlY29yYXRpb246bm9uZTt9DQouYm1oX2xpbmsgYXtwYWRkaW5nLWxlZnQ6IDFyZW07cG9zaXRpb246IHJlbGF0aXZlO2NvbG9yOiAjMzMzO2Rpc3BsYXk6IGlubGluZS1ibG9jazt9DQouYm1oX2xpbmsgYTo6YmVmb3Jle2NvbnRlbnQ6ICIiO21hcmdpbjogYXV0bztsZWZ0OiAwO3Bvc2l0aW9uOiBhYnNvbHV0ZTt0b3A6Y2FsYyguNXJlbSArIDFweCk7d2lkdGg6IDRweDtoZWlnaHQ6IDRweDtib3JkZXItdG9wOiAycHggc29saWQgIzMzMztib3JkZXItcmlnaHQ6IDJweCBzb2xpZCAjMzMzO3RyYW5zZm9ybTogcm90YXRlKDQ1ZGVnKTt9DQpkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXYsZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2LGRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdixmb3JtW2lkXj0iZm9ybWdyaWQxY29sIl0sZm9ybVtpZF49ImZvcm1ncmlkM2NvbCJdLGZvcm1baWRePSJmb3JtZ3JpZDRjb2wiXXtkaXNwbGF5OiBmbGV4O2ZsZXgtd3JhcDogd3JhcDt9DQpkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXY+ZGl2LGRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXYsZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdiwNCmRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2LGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2LGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2e3dpZHRoOiAxMDAlO30NCmRpdltpZF49Imxpc3RncmlkMmNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMiksZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobisyKSxkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLA0KZGl2W2lkXj0iZm9ybWdyaWQyY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMiksZGl2W2lkXj0iZm9ybWdyaWQzY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMiksZGl2W2lkXj0iZm9ybWdyaWQ0Y29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMil7bWFyZ2luLXRvcDogMzBweDt9DQouYm1oX2NhbGVuZGFyIGltZywuYm1oX2NhbGVuZGFyIGltZ3ttYXgtd2lkdGg6IDkwcHg7bWFyZ2luLWxlZnQ6IC41cmVtO30NCi5ibWhfY2FsZW5kYXIgc3BhbiwuYm1oX2NhbGVuZGFyPnNwYW4sLmJtaF9jYWxlbmRhcj5zcGFue2Rpc3BsYXk6IGZsZXg7YWxpZ24taXRlbXM6IGZsZXgtZW5kO2ZsZXgtd3JhcDogd3JhcDt9DQouYm1oX2NhbGVuZGFyPnNwYW4+aW5wdXQsLmJtaF9jYWxlbmRhcj5zcGFuPmlucHV0LC5ibWhfY2FsZW5kYXI+c3Bhbj5pbnB1dHt3aWR0aDogOXJlbTt9DQouYm1oX2NhbGVuZGFyPnNwYW4+aW1nOmxhc3QtY2hpbGR7bWFyZ2luLXRvcDogLjVyZW07fQ0KQG1lZGlhIChtaW4td2lkdGg6IDU3NnB4KSB7DQoJbGFiZWwge2Rpc3BsYXk6IGlubGluZS1ibG9jazt9DQp9DQpAbWVkaWEgKG1pbi13aWR0aDogNzY4cHgpIHsNCglkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDUwJSAtIDE1cHgpO21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoMm4pLGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgybil7bWFyZ2luLXJpZ2h0OiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpe21hcmdpbi10b3A6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMyksZGl2W2lkXj0iZm9ybWdyaWQ0Y29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMyl7bWFyZ2luLXRvcDogMzBweDt9DQoNCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDUwJSAtIDE1cHgpO21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoMm4pLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgybil7bWFyZ2luLXJpZ2h0OiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpe21hcmdpbi10b3A6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMyksZGl2W2lkXj0iZm9ybWdyaWQzY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMyl7bWFyZ2luLXRvcDogMzBweDt9DQoNCglkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDUwJSAtIDE1cHgpO21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQyY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoMm4pLGRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgybil7bWFyZ2luLXJpZ2h0OiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpe21hcmdpbi10b3A6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkMmNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMyksZGl2W2lkXj0iZm9ybWdyaWQyY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMyl7bWFyZ2luLXRvcDogMzBweDt9DQp9DQpAbWVkaWEgKG1pbi13aWR0aDogOTkycHgpIHsNCglkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDI1JSAtIDE4cHgpO21hcmdpbi1yaWdodDogMjRweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobisyKSxkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQobisyKXttYXJnaW4tcmlnaHQ6IDI0cHg7fQ0KCWRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKDRuKSxkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQoNG4pe21hcmdpbi1yaWdodDogMDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobiszKSxkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQobiszKXttYXJnaW4tdG9wOiAwO30NCg0KCWRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXYsZGl2W2lkXj0iZm9ybWdyaWQzY29sIl0+Zm9ybT5kaXZ7d2lkdGg6IGNhbGMoMzMuMzMzJSAtIDIwcHgpO21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoMm4pLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgybil7bWFyZ2luLXJpZ2h0OiAzMHB4O30NCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZCgzbiksZGl2W2lkXj0iZm9ybWdyaWQzY29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKDNuKXttYXJnaW4tcmlnaHQ6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKDMpLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgzKXttYXJnaW4tdG9wOiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzQpLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzQpe21hcmdpbi10b3A6IDMwcHg7fQ0KfQ==

QGNoYXJzZXQgIlVURi04IjsNCi8qISBub3JtYWxpemUuY3NzIHYzLjAuMiB8IE1JVCBMaWNlbnNlIHwgZ2l0LmlvL25vcm1hbGl6ZSAqLw0KKiwgKjo6YmVmb3JlLCAqOjphZnRlciB7LXdlYmtpdC1ib3gtc2l6aW5nOiBib3JkZXItYm94O2JveC1zaXppbmc6IGJvcmRlci1ib3g7fQ0KLmlubmVye21heC13aWR0aDogMTEyMHB4O21hcmdpbjogYXV0bzt3aWR0aDogOTQlO30NCnRhYmxle3dpZHRoOiAxMDAlO3RhYmxlLWxheW91dDogZml4ZWQ7Ym9yZGVyLWNvbGxhcHNlOiBjb2xsYXBzZX0NCnRoLHRke3BhZGRpbmc6IDFyZW07Ym9yZGVyOiAxcHggc29saWQgI2NjYzt9DQp0ZHt2ZXJ0aWNhbC1hbGlnbjogdG9wO30NCnVsLG9se3BhZGRpbmctbGVmdDogMjBweDt9DQpsaStsaXttYXJnaW4tdG9wOiAuNXJlbTt9DQpkdHtmb250LXdlaWdodDogYm9sZDt9DQpkZHttYXJnaW4tbGVmdDogMDttYXJnaW4tdG9wOiAuNXJlbTt9DQpkZCtkdHttYXJnaW4tdG9wOiAxcmVtO30NCmltZ3ttYXgtd2lkdGg6IDEwMCU7aGVpZ2h0OiBhdXRvfQ0KYSB7dGV4dC1kZWNvcmF0aW9uOiBub25lO2JhY2tncm91bmQtY29sb3I6IHRyYW5zcGFyZW50O30NCmE6aG92ZXIge3RleHQtZGVjb3JhdGlvbjogdW5kZXJsaW5lO30NCmlucHV0LHNlbGVjdCx0ZXh0YXJlYXtib3JkZXI6IDFweCBzb2xpZCAjY2NjO3BhZGRpbmc6IC4yNXJlbSAuNXJlbTt9DQppbnB1dCwgYnV0dG9uLCBzZWxlY3QsIG9wdGdyb3VwLCB0ZXh0YXJlYSB7bWFyZ2luOiAwO2ZvbnQtZmFtaWx5OiBpbmhlcml0O2ZvbnQtc2l6ZTogaW5oZXJpdDtsaW5lLWhlaWdodDogaW5oZXJpdDtvdXRsaW5lOiBub25lO30NCmxhYmVsIHtjdXJzb3I6IHBvaW50ZXI7ZGlzcGxheTogYmxvY2s7bWFyZ2luLWJvdHRvbTogLjI1cmVtO21hcmdpbi1yaWdodDogMXJlbTt9DQppbnB1dFt0eXBlPSd0ZXh0J117YXBwZWFyYW5jZTogbm9uZTstd2Via2l0LWFwcGVhcmFuY2U6IG5vbmU7LW1vei1hcHBlYXJhbmNlOiBub25lO3dpZHRoOiAxMDAlO30NCmlucHV0W3R5cGU9J2NoZWNrYm94J10saW5wdXRbdHlwZT0ncmFkaW8nXXttYXJnaW4tcmlnaHQ6IC41cmVtO30NCmlucHV0W3R5cGU9J3N1Ym1pdCdde2JvcmRlcjogbm9uZTtkaXNwbGF5OiBibG9jazttYXJnaW46IGF1dG87cGFkZGluZzogLjc1cmVtIDVyZW07Y3Vyc29yOiBwb2ludGVyO30NCi5ibWhfYnRuIGF7Ym9yZGVyLXJhZGl1czogMTAwdmg7YmFja2dyb3VuZC1jb2xvcjogIzk5OTtwYWRkaW5nOiAuNzVyZW07Y29sb3I6ICNmZmY7dGV4dC1kZWNvcmF0aW9uOiBub25lO2Rpc3BsYXk6IGlubGluZS1ibG9jazt9DQouYm1oX2J0biBhIHNwYW57cG9zaXRpb246IHJlbGF0aXZlO3BhZGRpbmctcmlnaHQ6IDJyZW07cGFkZGluZy1sZWZ0OiAxLjVyZW07ZGlzcGxheTogaW5saW5lLWJsb2NrO30NCi5ibWhfYnRuIGEgc3Bhbjo6YWZ0ZXJ7Y29udGVudDogIiI7bWFyZ2luOiBhdXRvO3JpZ2h0OiAuNXJlbTtwb3NpdGlvbjogYWJzb2x1dGU7dG9wOiAwO2JvdHRvbTogMDt3aWR0aDogNnB4O2hlaWdodDogNnB4O2JvcmRlci10b3A6IDJweCBzb2xpZCAjZmZmO2JvcmRlci1yaWdodDogMnB4IHNvbGlkICNmZmY7dHJhbnNmb3JtOiByb3RhdGUoNDVkZWcpO30NCi5ibWhfYnRuIGE6aG92ZXJ7YmFja2dyb3VuZC1jb2xvcjogIzc3Nzt0ZXh0LWRlY29yYXRpb246bm9uZTt9DQouYm1oX2xpbmsgYXtwYWRkaW5nLWxlZnQ6IDFyZW07cG9zaXRpb246IHJlbGF0aXZlO2NvbG9yOiAjMzMzO2Rpc3BsYXk6IGlubGluZS1ibG9jazt9DQouYm1oX2xpbmsgYTo6YmVmb3Jle2NvbnRlbnQ6ICIiO21hcmdpbjogYXV0bztsZWZ0OiAwO3Bvc2l0aW9uOiBhYnNvbHV0ZTt0b3A6Y2FsYyguNXJlbSArIDFweCk7d2lkdGg6IDRweDtoZWlnaHQ6IDRweDtib3JkZXItdG9wOiAycHggc29saWQgIzMzMztib3JkZXItcmlnaHQ6IDJweCBzb2xpZCAjMzMzO3RyYW5zZm9ybTogcm90YXRlKDQ1ZGVnKTt9DQpkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXYsZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2LGRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdixmb3JtW2lkXj0iZm9ybWdyaWQiXSB7ZGlzcGxheTogZmxleDtmbGV4LXdyYXA6IHdyYXA7fQ0KZGl2W2lkXj0ibGlzdGdyaWQyY29sIl0+ZGl2PmRpdixkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2LGRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdj5kaXYsDQpkaXZbaWRePSJmb3JtZ3JpZDJjb2wiXT5mb3JtPmRpdixkaXZbaWRePSJmb3JtZ3JpZDNjb2wiXT5mb3JtPmRpdixkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdnt3aWR0aDogMTAwJTt9DQpkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMiksZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobisyKSwNCmRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpLGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzIpe21hcmdpbi10b3A6IDMwcHg7fQ0KLmJtaF9jYWxlbmRhciBpbWcsLmJtaF9jYWxlbmRhciBpbWd7bWF4LXdpZHRoOiA5MHB4O21hcmdpbi1sZWZ0OiAuNXJlbTt9DQouYm1oX2NhbGVuZGFyIHNwYW4sLmJtaF9jYWxlbmRhcj5zcGFuLC5ibWhfY2FsZW5kYXI+c3BhbntkaXNwbGF5OiBmbGV4O2FsaWduLWl0ZW1zOiBmbGV4LWVuZDtmbGV4LXdyYXA6IHdyYXA7fQ0KLmJtaF9jYWxlbmRhcj5zcGFuPmlucHV0LC5ibWhfY2FsZW5kYXI+c3Bhbj5pbnB1dCwuYm1oX2NhbGVuZGFyPnNwYW4+aW5wdXR7d2lkdGg6IDlyZW07fQ0KLmJtaF9jYWxlbmRhcj5zcGFuPmltZzpsYXN0LWNoaWxke21hcmdpbi10b3A6IC41cmVtO30NCkBtZWRpYSAobWluLXdpZHRoOiA1NzZweCkgew0KCWxhYmVsIHtkaXNwbGF5OiBpbmxpbmUtYmxvY2s7fQ0KfQ0KQG1lZGlhIChtaW4td2lkdGg6IDc2OHB4KSB7DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdixkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdnt3aWR0aDogY2FsYyg1MCUgLSAxNXB4KTttYXJnaW4tcmlnaHQ6IDMwcHg7fQ0KCWRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKDJuKSxkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQoMm4pe21hcmdpbi1yaWdodDogMDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobisyKSxkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQobisyKXttYXJnaW4tdG9wOiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzMpLGRpdltpZF49ImZvcm1ncmlkNGNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzMpe21hcmdpbi10b3A6IDMwcHg7fQ0KDQoJZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdixkaXZbaWRePSJmb3JtZ3JpZDNjb2wiXT5mb3JtPmRpdnt3aWR0aDogY2FsYyg1MCUgLSAxNXB4KTttYXJnaW4tcmlnaHQ6IDMwcHg7fQ0KCWRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKDJuKSxkaXZbaWRePSJmb3JtZ3JpZDNjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQoMm4pe21hcmdpbi1yaWdodDogMDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobisyKSxkaXZbaWRePSJmb3JtZ3JpZDNjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQobisyKXttYXJnaW4tdG9wOiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzMpLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzMpe21hcmdpbi10b3A6IDMwcHg7fQ0KDQoJZGl2W2lkXj0ibGlzdGdyaWQyY29sIl0+ZGl2PmRpdixkaXZbaWRePSJmb3JtZ3JpZDJjb2wiXT5mb3JtPmRpdnt3aWR0aDogY2FsYyg1MCUgLSAxNXB4KTttYXJnaW4tcmlnaHQ6IDMwcHg7fQ0KCWRpdltpZF49Imxpc3RncmlkMmNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKDJuKSxkaXZbaWRePSJmb3JtZ3JpZDJjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQoMm4pe21hcmdpbi1yaWdodDogMDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQyY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobisyKSxkaXZbaWRePSJmb3JtZ3JpZDJjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQobisyKXttYXJnaW4tdG9wOiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDJjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZChuKzMpLGRpdltpZF49ImZvcm1ncmlkMmNvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZChuKzMpe21hcmdpbi10b3A6IDMwcHg7fQ0KfQ0KQG1lZGlhIChtaW4td2lkdGg6IDk5MnB4KSB7DQoJZGl2W2lkXj0ibGlzdGdyaWQ0Y29sIl0+ZGl2PmRpdixkaXZbaWRePSJmb3JtZ3JpZDRjb2wiXT5mb3JtPmRpdnt3aWR0aDogY2FsYygyNSUgLSAxOHB4KTttYXJnaW4tcmlnaHQ6IDI0cHg7fQ0KCWRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMiksZGl2W2lkXj0iZm9ybWdyaWQ0Y29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMil7bWFyZ2luLXJpZ2h0OiAyNHB4O30NCglkaXZbaWRePSJsaXN0Z3JpZDRjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZCg0biksZGl2W2lkXj0iZm9ybWdyaWQ0Y29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKDRuKXttYXJnaW4tcmlnaHQ6IDA7fQ0KCWRpdltpZF49Imxpc3RncmlkNGNvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKG4rMyksZGl2W2lkXj0iZm9ybWdyaWQ0Y29sIl0+Zm9ybT5kaXY6bnRoLWNoaWxkKG4rMyl7bWFyZ2luLXRvcDogMDt9DQoNCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2LGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2e3dpZHRoOiBjYWxjKDMzLjMzMyUgLSAyMHB4KTttYXJnaW4tcmlnaHQ6IDMwcHg7fQ0KCWRpdltpZF49Imxpc3RncmlkM2NvbCJdPmRpdj5kaXY6bnRoLWNoaWxkKDJuKSxkaXZbaWRePSJmb3JtZ3JpZDNjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQoMm4pe21hcmdpbi1yaWdodDogMzBweDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQoM24pLGRpdltpZF49ImZvcm1ncmlkM2NvbCJdPmZvcm0+ZGl2Om50aC1jaGlsZCgzbil7bWFyZ2luLXJpZ2h0OiAwO30NCglkaXZbaWRePSJsaXN0Z3JpZDNjb2wiXT5kaXY+ZGl2Om50aC1jaGlsZCgzKSxkaXZbaWRePSJmb3JtZ3JpZDNjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQoMyl7bWFyZ2luLXRvcDogMDt9DQoJZGl2W2lkXj0ibGlzdGdyaWQzY29sIl0+ZGl2PmRpdjpudGgtY2hpbGQobis0KSxkaXZbaWRePSJmb3JtZ3JpZDNjb2wiXT5mb3JtPmRpdjpudGgtY2hpbGQobis0KXttYXJnaW4tdG9wOiAzMHB4O30NCn0=

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.

Copyright © 2025 Nachi-fujikoshi corp. All Rights Reserved.